Quality Management

Control at Every Step, Confidence in Every Product

Incoming, In-Process, and Final Quality Control

Every stage of our production is monitored in accordance with ISO 9001:2015 quality management principles and automotive industry–specific quality standards, ensuring not only the final product but the entire process is secured.

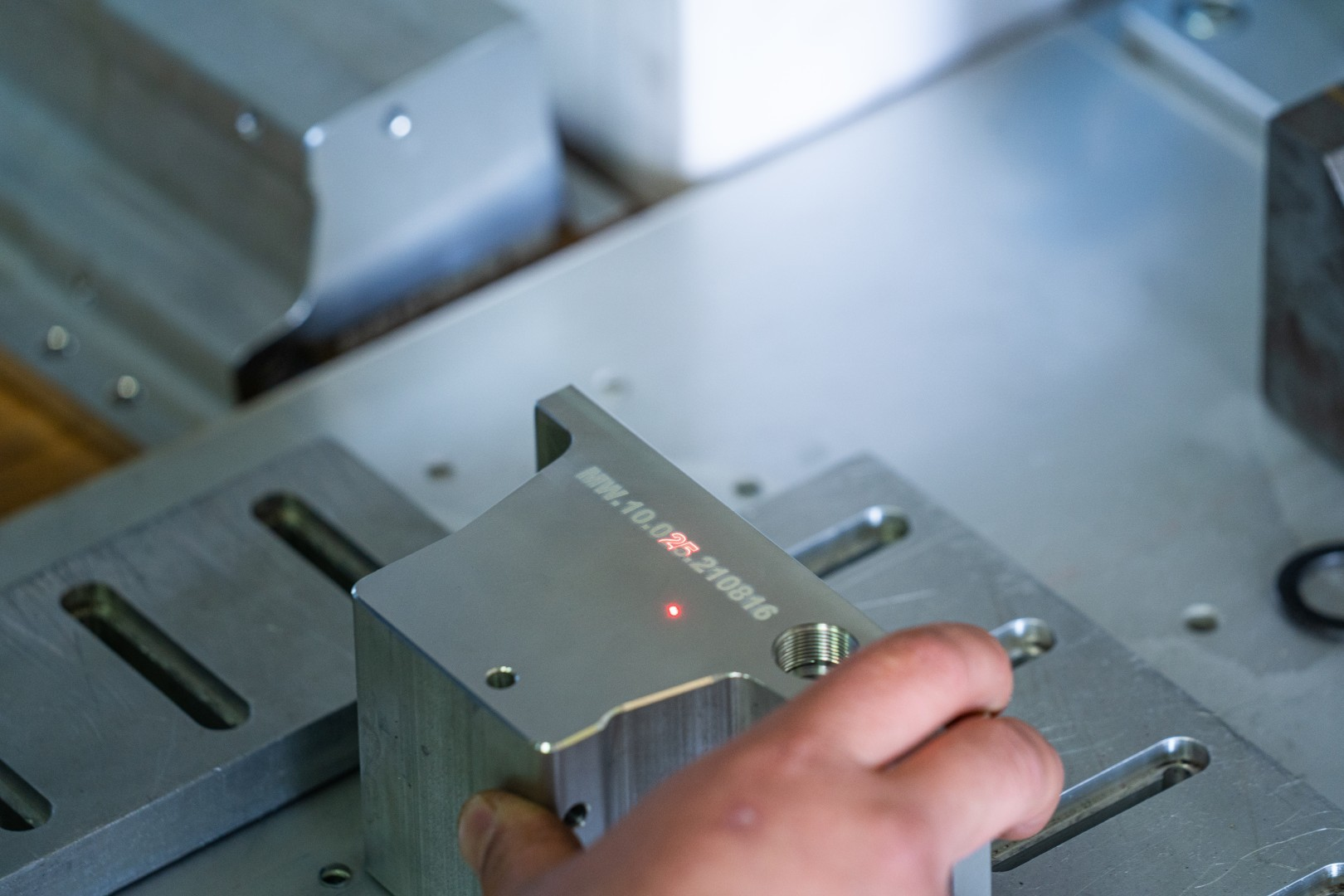

* Incoming Quality Control: Raw materials and supplied parts undergo detailed measurements, certificate verification, and visual inspection prior to acceptance. Only approved materials proceed to production.

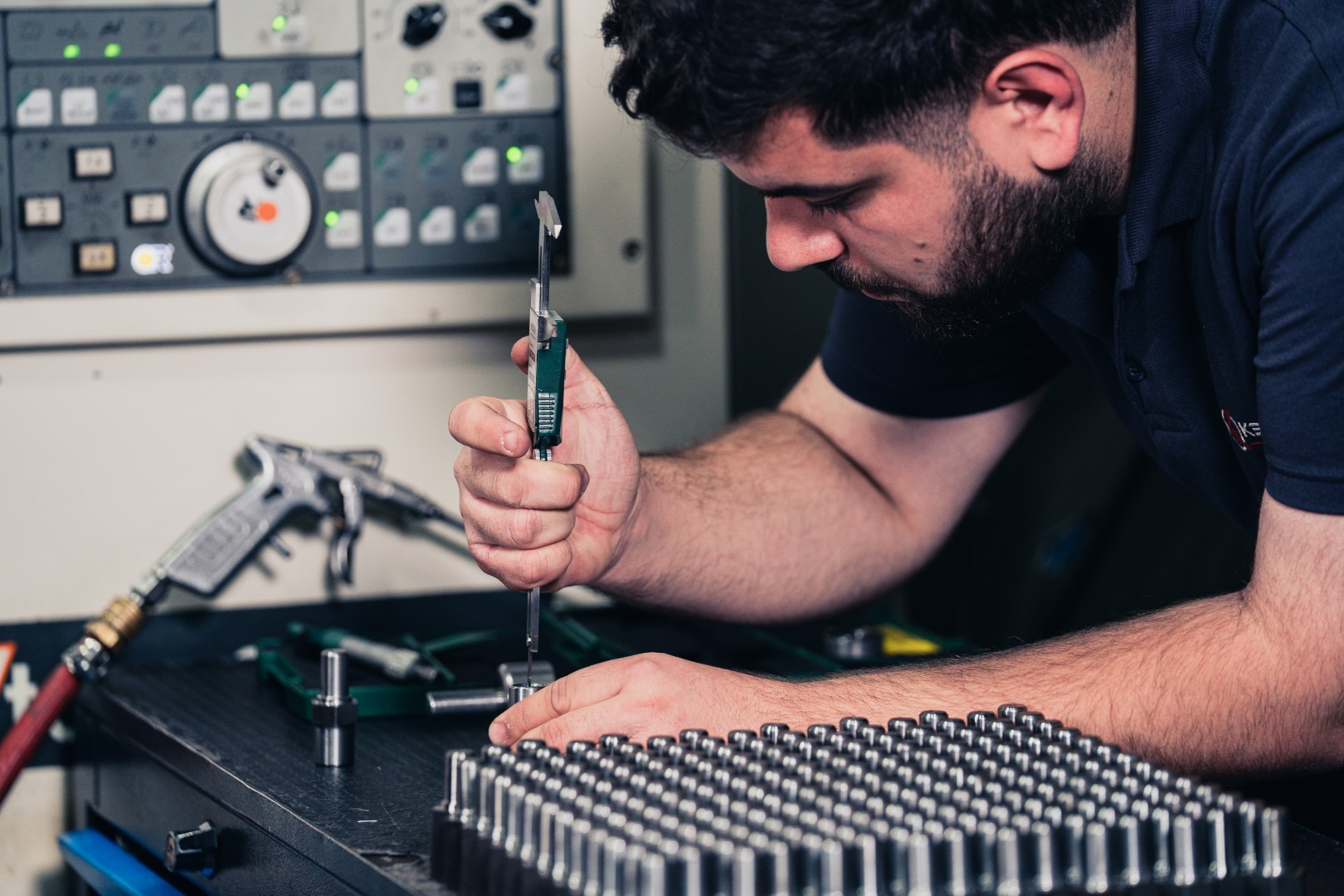

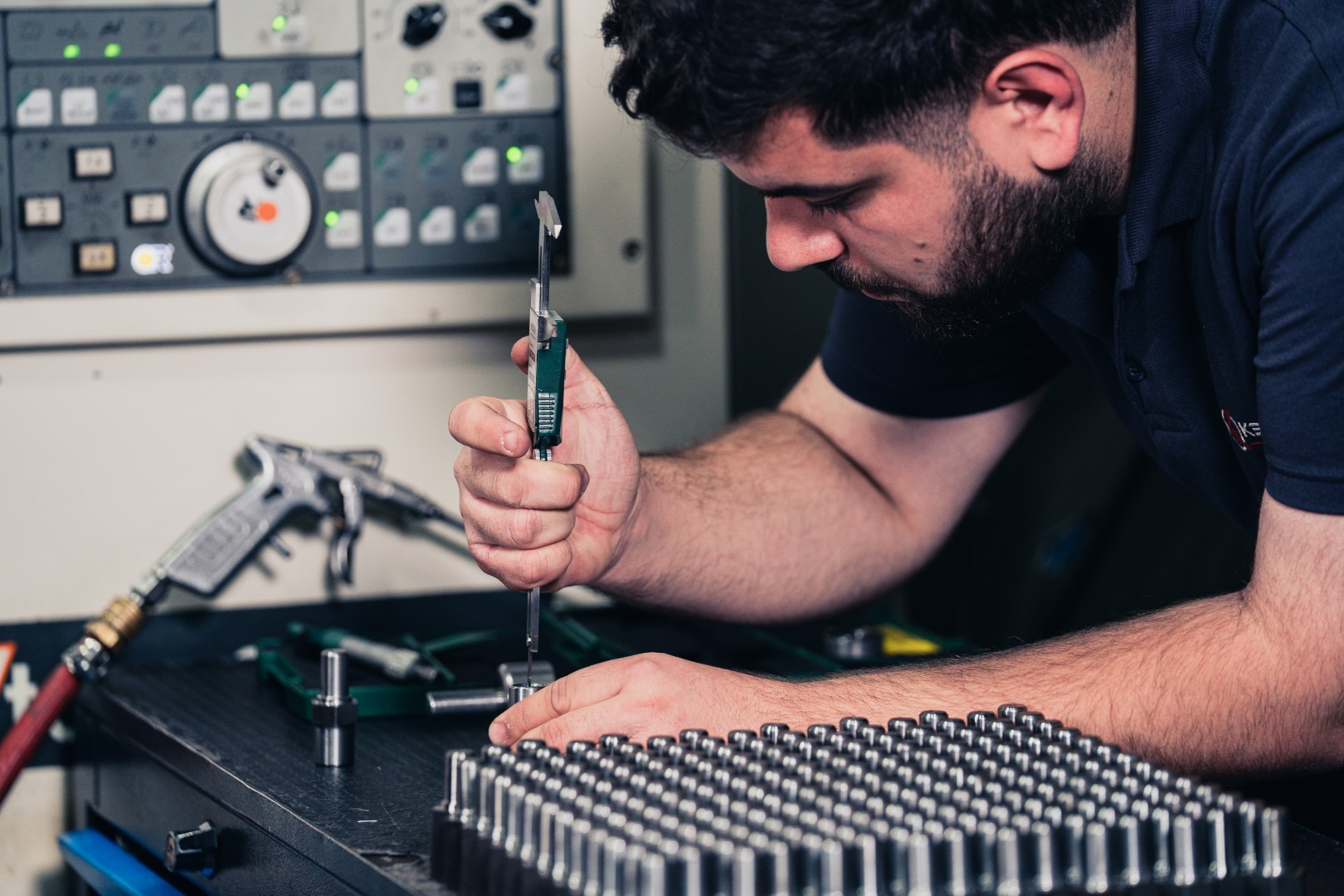

* In-Process Controls: Measurements and tests are conducted at critical operation points. Using Process FMEA, Control Plans (CP), and Statistical Process Control (SPC) methods, process reliability is continuously ensured.

* Final Quality Control: Finished products are subjected to dimensional measurements, functional tests, and visual inspections.

Depending on customer requirements, PPAP documentation and special test certificates are prepared. Through this structure, we provide our customers not only with consistent quality and full traceability, but also with documentation fully compliant with international OEM and Tier-1 standards.

High-Precision Measurement Compliant With International Standards

Inspection and Test Equipment

Our measurement and testing equipment used in quality control processes are managed under a regular calibration program to ensure high precision and reliability. Through these systems, we verify the dimensional accuracy, material properties, and surface quality of our products in accordance with international standards and customer requirements.

| Type | Description |

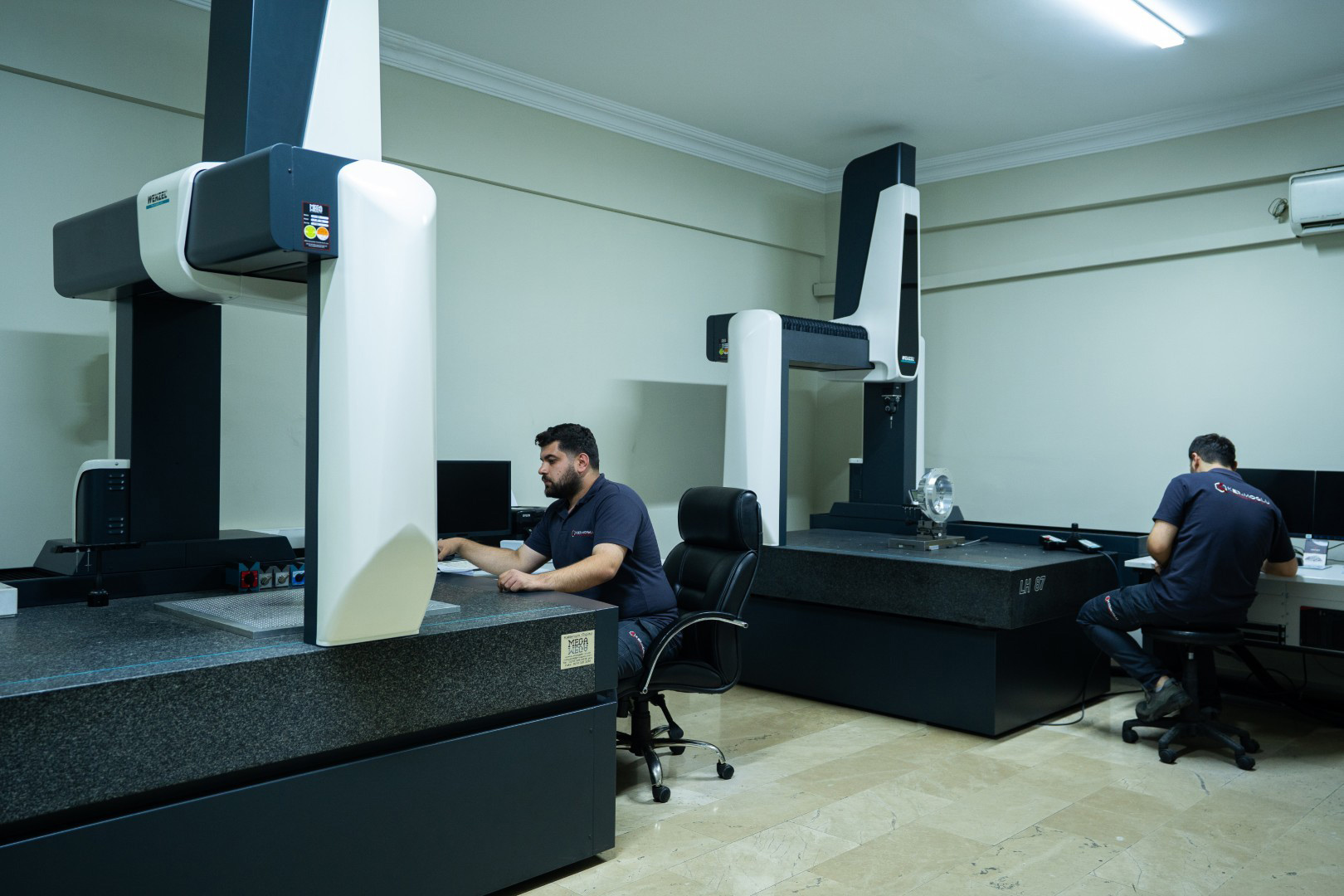

| 3D CMM – WENZEL LH87 – PH20 Motorize PRO | Equipped with the 5-axis PH20 motorized probe head, the Wenzel LH87 CMM ensures high speed, flexible accessibility, and exceptional repeatability in three-dimensional measurement processes. This advanced technology delivers accuracy and reliability in accordance with international standards for both prototype and serial production parts, even with complex geometries. |

| 3D CMM – WENZEL LH87 – PH10 | Our Wenzel LH87 CMM systems feature both PH10 and PH20 probe technologies, combining the stability and repeatability of the PH10 with the five-axis speed and flexibility of the PH20. This versatility ensures exceptional accuracy and reliability across diverse part geometries, delivering precise measurement results from prototype development to mass production. |

| Brinell Hardness Tester / BH-3000B | The BH-3000B Brinell hardness tester measures the mechanical strength of large cross-section parts with precision, ensuring consistency and accuracy in hardness values during production. |

| Rockwell Hardness Testing Machine / HR-530-530L | The HR-530 Rockwell hardness testing machine provides fast and reliable hardness measurements for various materials, ensuring compliance with international standards. |

| Mikro Vickers Hardness Tester / HM-200A | With the HM-200A device, microhardness values of thin coatings and small samples are measured with high precision, enabling accurate monitoring of heat treatment quality. |

| Metallurgical Microscope | The metallurgical microscope is used to analyze structural changes in materials after heat treatment and surface hardening, forming an essential part of our process optimization and quality assurance activities. |

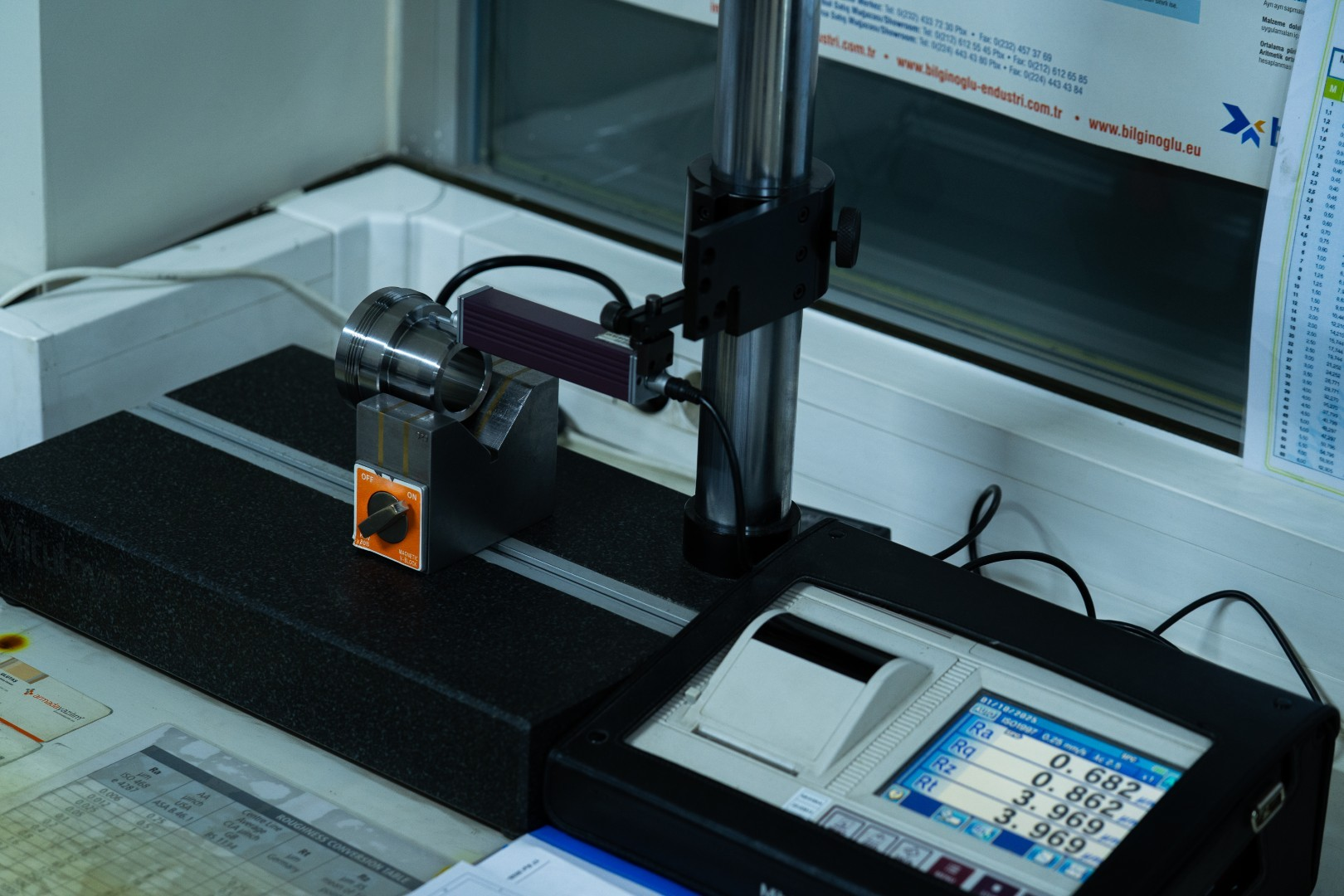

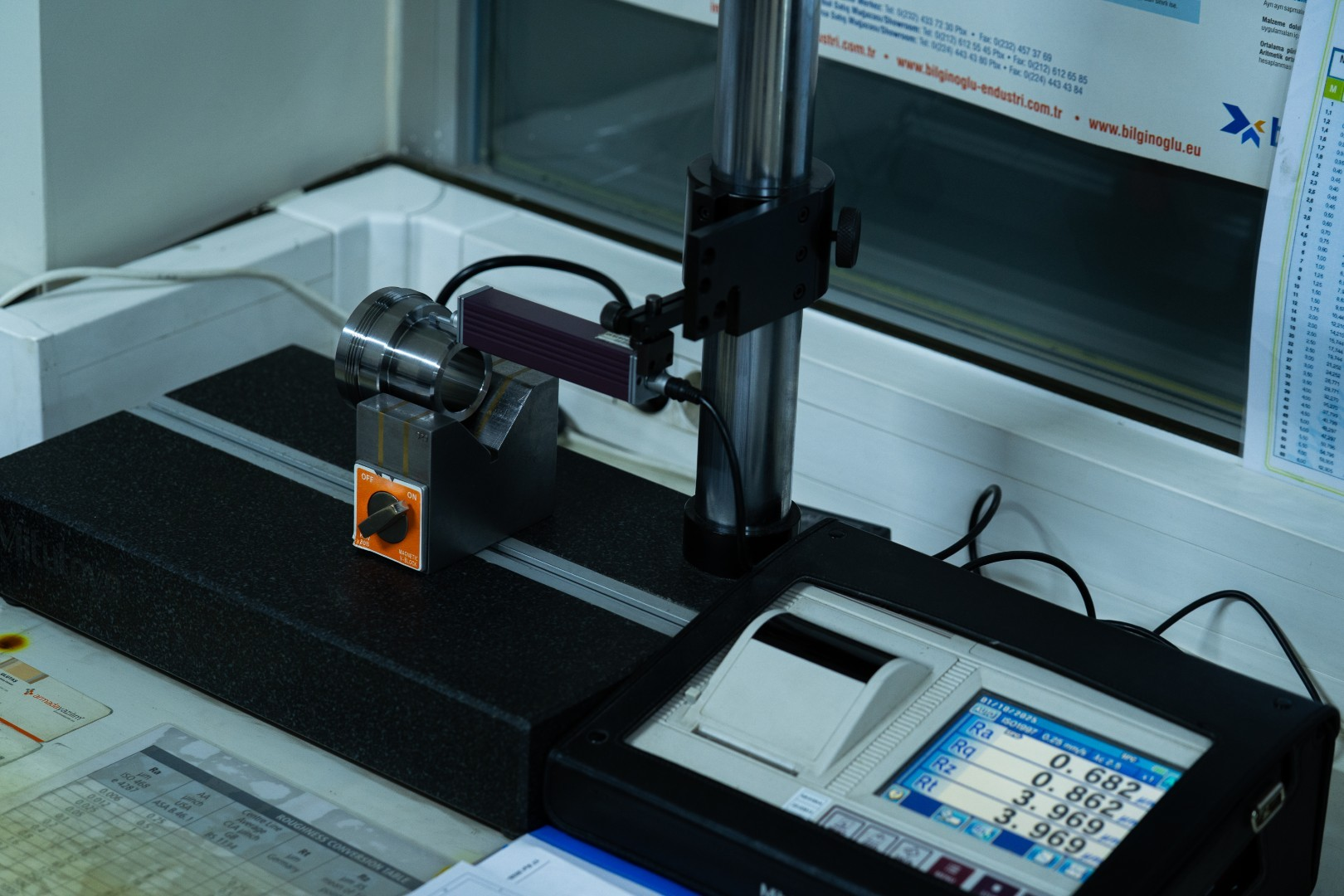

| Surface Roughness Tester / Surftest | The Surftest surface roughness tester evaluates the surface texture of machined parts, confirming that surface quality meets international and customer-specific standards. |

| Metallographic Cutting Machine / / IMPRO PROCUT-UM | The IMPRO PROCUT-UM cutting device, used for metallographic testing, enables the preparation of samples and ensures precise cross-sections for accurate analysis. |

| Hot Mounting Press Machine / IMPRO H007 | During the sample preparation process, the IMPRO H007 Bakelite hot mounting press is used to mount samples securely for consistent and reliable testing results. |

| Polishing Machines | In the polishing stage, the PMV009 device provides smooth and reflective sample surfaces for microscopic analysis and precise inspection results. |

| Crack Detection Device / Karl Deutsch | The Karl Deutsch crack detection device uses magnetic particle and penetrant testing methods to identify surface cracks and defects, ensuring safety in critical applications. |

| Post-Assembly Hydraulic Test System / PLS | Products leaving the production line is functionally tested using the PLS post-assembly hydraulic test system. This process ensures that assembly-related faults or potential leakages are detected before leaving the production area, enabling zero-defect delivery to our customers. |

| Braking Systems Test Device / PLS | The PLS hydraulic test device, specifically designed for brake systems, performs durability and performance tests under high pressure, ensuring that all brake components fully comply with safety standards. |

| Horizontal Runout Measurement Device | The runout control device, used to enhance part precision, plays a critical role in detecting concentricity and axis deviations. This equipment ensures that components are consistently manufactured within quality standards throughout the production process. |

Certified Quality, Trusted Brand

Standards and Certifications

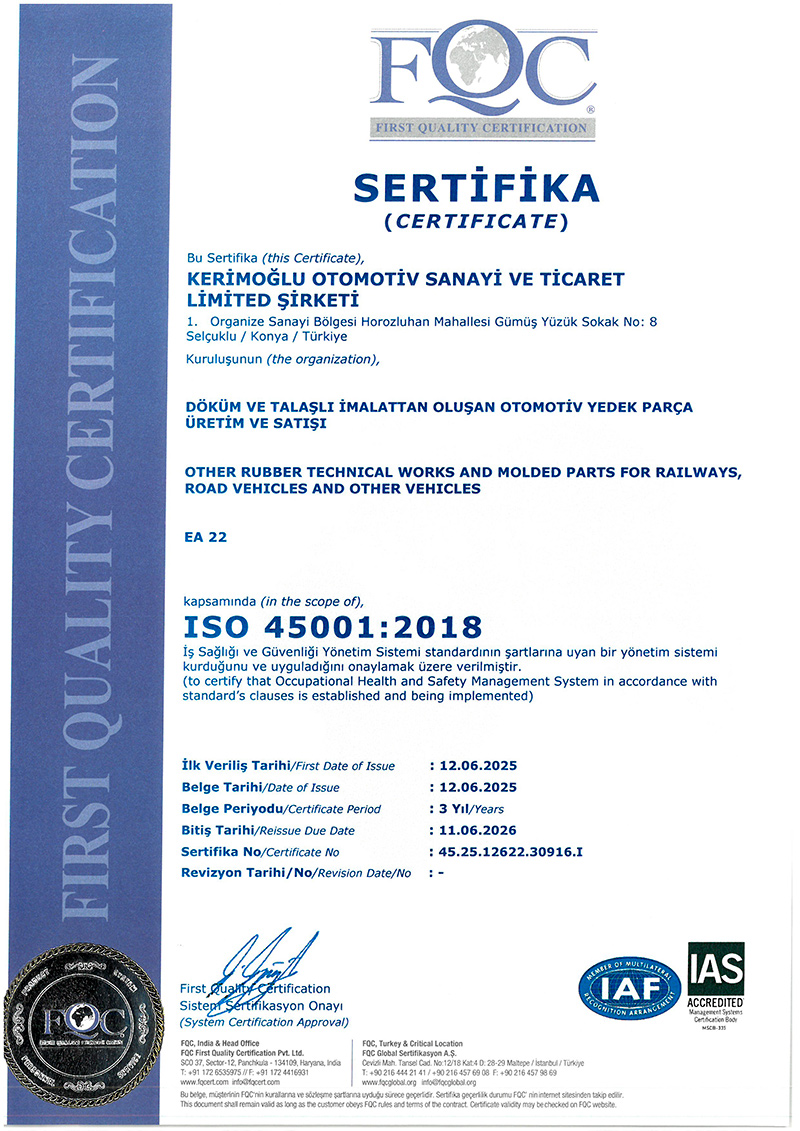

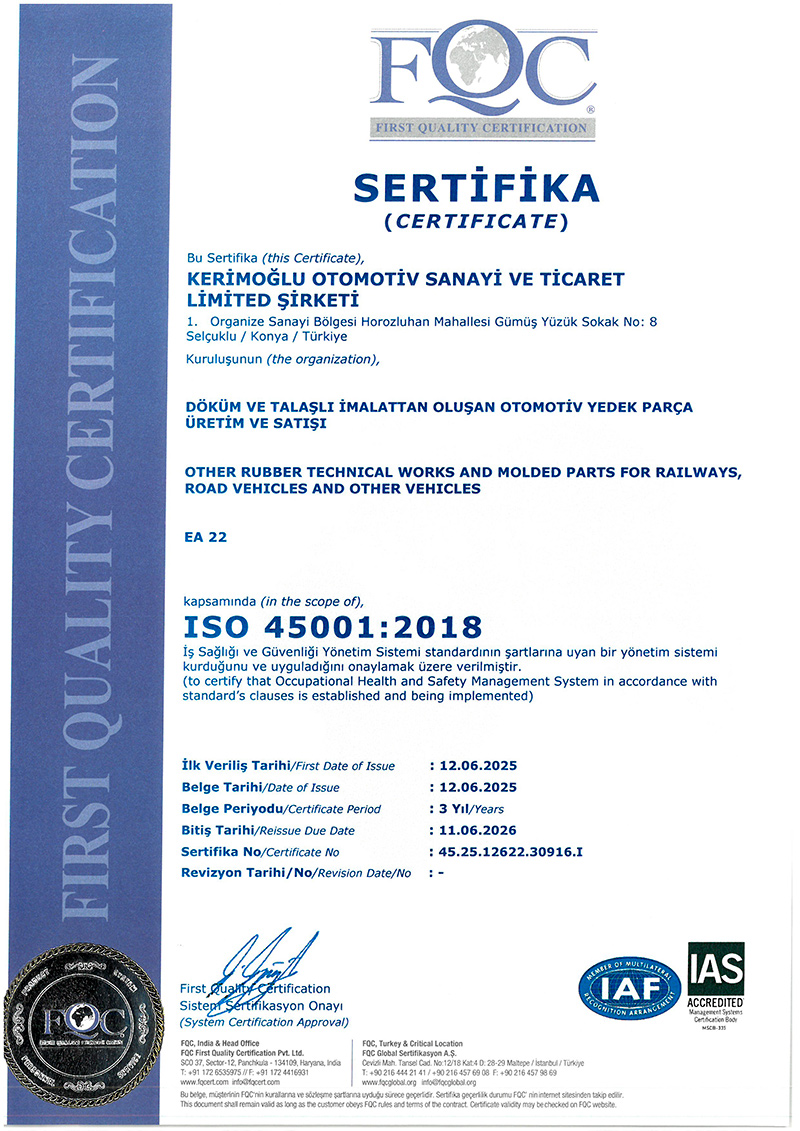

To ensure sustainable quality and full compliance with international standards, all our operations are carried out within the framework of certified management systems.

* ISO 9001:2015 – Quality Management System

* ISO 14001 – Environmental Management System

* ISO 45001 – Occupational Health and Safety Management System

* Trademark Registration Certificate

Safe and Transparent Manufacturing

Traceability and Documentation

All our production processes are documented in full compliance with the ISO 9001:2015 Quality Management System requirements. Every stage — from raw material intake to final product — is tracked and recorded through lot numbers and product IDs. For each item, comprehensive product files are created, including technical drawings, process parameters, quality control results, and shipment details. Through ERP integration, records are securely stored in digital form, ensuring traceability, audit compliance, and full transparency for our customers.

Kerimoğlu Otomotiv ©2025

Designed By: FlashJedi

Türkçe

Türkçe English

English Deutsch

Deutsch русский

русский Español

Español